Big Belton Blaze: Making the Case for Combustible Dust Safety

Indeco Sales and Maco Manufacturing experienced a fire that quickly spread within its main manufacturing space and to adjacent facilities. The unfortunate timing impacted their manufacturing employees who were actively working when the fire started. In this type of scenario, properly designed and installed safety devices prevent or mitigate widespread damage due to an explosive event.

Combustible Dust Risk in Wood Manufacturing Facilities

A fire started on the morning of December 5, 2007 in a Belton, TX at a school and library furniture manufacturing facility. The local and regional fire departments fought this raging fire for two days before Indeco Sales and Maco Manufacturing was reduced to a pile of charred rubble. The Belton fire chief recalled that the fire likely started when a board got stuck on a conveyer line and caught fire. Embers were then picked up by the dust collector, which accelerated the fire through the facility. The property quickly engulfed in flames as it spread through the 300,000-square-foot complex. No one was injured, but it resulted in an inventory and equipment loss of more than $10 million along with undue stress for owners, 100+ employees, customers and the local community. .

A Case for Explosion Isolation Safety Devices

A proper wood dust extraction system is required to protect people, property and production from the harmful effects of nuisance dusts and shavings created by woodworking, manufacturing or milling processes. Wood dust is combustible, so proper safeguards must be in place to ensure that wood dust explosions are prevented and if they do occur widespread damage is minimized to protect employees and production.

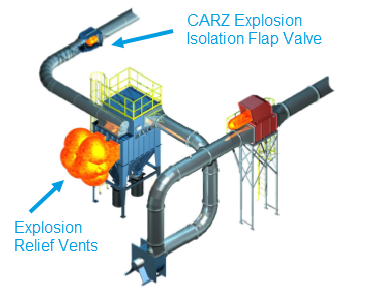

Manufacturers also need to be compliant with various regulations, such as OSHA and NFPA. NFPA 664 Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities outlines the requirements for manufacturers that handle combustible wood dust to properly install isolation devices to prevent a flame propagation from traveling back into a given work area as experienced by Indeco. The design and use of these devices can be consulted by a Nederman combustible dust expert and the CARZ Explosion Isolation Flap Valve fulfills these requirements.

If proper explosion isolation was installed, damage would have been reduced significantly by containing the created energy and fire to the exterior building where the fire started. A spark detection and extinguishment system installed in the pipe system would prevent this type of fire and explosion in the dust collector as well.

A CARZ Explosion Isolation Flap Valve is positioned downstream of the dust collector in the pipe system. If an explosive event were to occur, it will block the pressure and flame front from transferring back into the workspace.

Note: The CARZ Valve must be installed a certain distance from the dust collector to be able to properly react to an explosion process that could happen in less than ½ second.

For a dust collection system handling wood dust, an explosion and fire risk exists in the dust collector. If competent igniters from process malfunctions are introduced into this vessel, an explosion and or fire will most likely result. An explosion will create a high pressure spike and flame front that will propagate through the interconnecting process and clean air return pipe systems back into the interior workspace.

The CARZ Explosion Isolation Flap-Valve closes and blocks the path of the flame from traveling back into the workplace during an explosive event in the dust collector.

In an explosion scenario, properly designed and installed safety devices will prevent and mitigate widespread damage like experienced in this case.

Watch the CARZ Explosion Isolation Flap-Valve in action:

Nederman has combustible dust expertise to help design a safe and compliant dust collection system fully equipped with the necessary devices to ensure you protect your people, plant and production from the dangerous effects of combustible wood dust. Don’t let your facility become the next big Belton blaze. Contact us today!

Loading...