Solutions for dust and fume extraction in a 3D printing work environment

The popularity of 3D printing, or additive manufacturing, has increased greatly in the past few years. Because of this, it is important to raise awareness of the potential health hazards associated with using the technology. In this blog article, you will learn more about this as well as get an insight into how we provide Swerea IVF with fume and dust extraction solutions for their 3D printing research laboratory.

A rapidly growing industry characterized by innovation

The possibilities of creating customized products with minimal waste and low manufacturing costs have led the 3D printing industry, and the technologies behind it, to grow and develop rapidly. Previously, 3D printers were mostly used for creating smaller quantities of prototyping parts. Today, engineers are 3D printing everything from bone replacements to aircraft and houses, with new possibilities presenting themselves constantly.

Increased awareness of hazardous fumes and combustible dust from 3D printing processes

As more and more companies use 3D printing in their operations, questions have been raised regarding associated health and safety issues. There is a concern about the fumes, dust and odors created during the printing and post processes. With 3D printing being a relatively young industry, scientists have only recently begun to investigate this. And there are studies indicating potential health risks associated with using the technologies. This is the case regardless if you are using the printing process of, for example, material extrusion, binder jetting or powder bed fusion. Study results show that printers emit a significant amount of ultrafine particles (UFPs) and hazardous volatile organic compounds (VOCs). Post processes of gluing, grinding and painting the product have also been shown to generate potentially hazardous pollutants.

Depending on which material and printing process you are working with, the pollutants can be both combustible and cause various health problems if inhaled. This applies especially in cases of large-scale manufacturing where several machines run simultaneously. Good ventilation and customized fume and dust extraction systems are therefore important to ensure a safe work environment.

Additive Manufacturing Research Laboratory at Swerera IVF

As a provider of clean air solutions, Nederman is participating in the construction of an additive manufacturing research laboratory at Swerea IVF. The Swedish research institute conducts research for industrial renewal and sustainable development. One of their current projects is to set up a production line for additive manufacturing of metallic materials. The aim is to facilitate the industrialization of additive manufacturing by creating a platform for innovative products, materials and processes. In addition, the research laboratory will function as a showroom to display 3D printing applications to interested parties.

Providing extraction solutions for desktop 3D printers and large-scale manufacturing

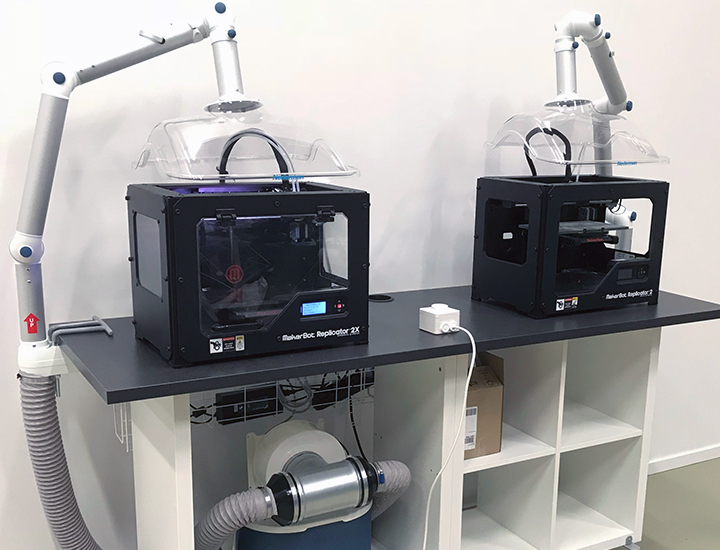

The Additive Manufacturing Research Laboratory includes desktop 3D printers as well as a system for large-scale manufacturing. Nederman is providing air filtration and fume extraction solutions for both of these areas. As for now, we have installed benchtop extraction kits for the desktop 3D printers. The kits include a fan, filter, fan speed controller, hoses, table brackets and connectors. Next, we will provide a fume and dust extraction solution for the large-scale manufacturing system. Our solution will extract fumes during the printing process and dust during the machining process. This is done using the same vacuum unit.

In all of the applications described, ultrafine particles, volatile organic compounds, and dust are captured at the source of pollution, before they reach the operator’s breathing zone. The result is a safe and clean work environment where several 3D printers can run simultaneously without causing health risks.

We are excited about being a part of this project together with Swerea, and to see where 3D printing technologies will take the manufacturing industry in the future!

At Nederman, we continually develop our solutions for fume and dust extraction to keep up with the progressions in the market. Are you using 3D printing in your workplace? We can help you create a safe and sustainable working environment by recommending suitable equipment and routines. Contact us if you have any questions!

Photo: Swerea IVF.

Loading...