Driving Sustainability with Nederman Dust Control Solutions

McLaren Automotive upgrades their Formula 1 factory with higher efficiency Nederman extraction and air filtration system

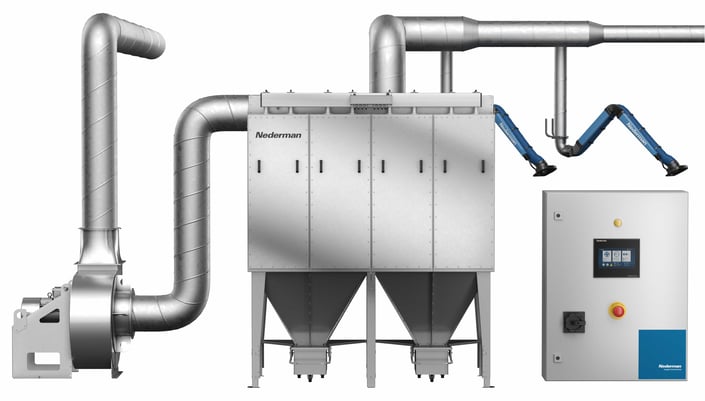

In the pursuit of net-zero sustainability by 2040, McLaren analyzed their manufacturing process and identified key areas to improve sustainability, process efficiency and workplace safety. McLaren, the 2nd oldest active and most successful Formula 1 team, repurposed their old Formula 1 factory into a new composites factory. Their factory expansion and new equipment upgrades fueled production capacity and ability to scale operation for future growth with reduced costs and turnaround times. A central dust collection system from Nederman was a critical component to achieve these goals.

Optimizing Production Processes to Achieve Improved Efficiency and Safety

McLaren wanted to design a sustainable factory from the ground up for optimized material flow. Working with a cost cap meant ensuring effective spending to squeeze out every last ounce of performance. Any gains obtained through this redesign and restructure was a good investment, as it has resulted in an environment that produces more parts in-house quickly and efficiently. Explosion relief panels were installed to the filter that in the event of explosions, the vents will open and transmit it away from the workshop.

The existing dust extraction system was not powerful or durable enough to deal with the dust volumes generated in the manufacturing process, resulting in a dusty workplace that proved to be a health and safety hazard to workers. The extensive clean up processes resulted in excessive reliance on PPE. Manual clean-up operations resulted in less time producing components, increasing turnaround times and negatively impacting productivity. The dust extraction system machine operation was noisy and inefficient as well, which negatively impacted the work environment and proved to be costly. McLaren needed a properly sized dust extraction system with modern features to improve sustainability, efficiency, and workplace cleanliness. McLaren turned to Nederman to deal with potentially volatile dust particulate volumes, filter the air and vent it completely clean to the atmosphere.

“It’s a more sustainable system as it ramps up and down. It’s not running if the machines aren’t running. We get a much more efficient use of the electricity we are putting in with a much better draw out of the system tray.”, Ross, Composite Factory Director, McLaren Racing

“I go home clean now. Before, I would jump in my car and wipe dust off of my forehead… I don’t get that anymore”, Andy, Composite Technician, McLaren Racing

The value of clean air in a Formula 1 factory

- Healthier and safer working environment

- Reduced environmental impact

- Lower operation and maintenance cost

If you would like to speak to us, please contact our clean air experts.

Loading...