Nanofiber filter media increase the efficiency and life span of your dust collection and fume extraction system

Blended paper media have been used in industrial dust collection and fume extraction systems for decades. Made up of cellulose (80-85%) and polyester (15-20%) fibers, they collect particles in a variety of dust, fume and/or smoke generating applications, such as metalworking, welding, plasma cutting and laser cutting. With the advancement and availability of nanofiber technology, these filters are now able to collect more – and smaller – particles than ever before, while at the same time lasting longer, using less fan and compressed air energy, and requiring less maintenance than their predecessors

What are nanofiber filter media?

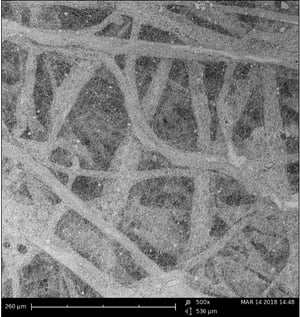

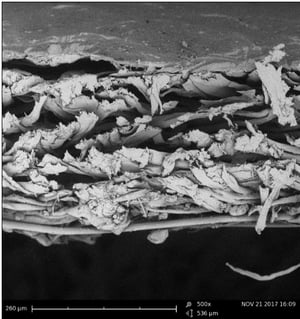

Nanofiber itself is a synthetic polymer fiber, typically smaller than 200 nanometers and commonly found smaller than 100 nanometers in diameter, that is applied through a spraying process to the top of a filter media to enhance its filtration properties; higher efficiency and better cleanability. When viewed through a high power microscope, such as scanning electron microscope (SEM), you can clearly see a layer of very fine fibers that create what looks like a super fine screen sitting on top of the carrier media or substrate. Image 1 below is a top view of the nanofiber screen atop a blended paper media. The very small nanofibers are approximately 100 nanometers with the larger fibers seen underneath approximately 20 microns (20,000 nanofibers) and larger. It´s this super fine screen that provides all the benefits. Image 2 shows a cross section of the full media. At the top of the image, you can see how thin the nanofiber layer is compared to the rest of the paper media, about 1/3000th as thick. It can be hard to believe that something so small can be of so much value in air filtration.

|

|

| Image 1 Top view of nanofiber | Image 2 Side view, nanofiber on 80/20 blender paper |

Surface loading vs depth loading filtration

For decades in the air filtration industry, filters and filtration systems were designed such that high efficiency would only be achieved after hours to weeks of operation. At the start-up of a system with new filters, the filters would first need to get dirty before they would provide the expected efficiency. As dirt gets stuck in the depth of the filter fibers and builds a thin layer over the surface of the filter, this first dust remains there over the life of the filter. Its called a dust cake. Even the strongest pulse cleaning does not remove this initial fine layer of dust. This is what is called depth loading filtration and in many systems using traditional cartridge media, system performance is dictated by this surface loaded dust layer.

Surface loading filtration is where the surface of the filter media does not allow dust to penetrate into the depth of the filter media. Dust is stopped on the surface, can build-up on the surface and when its time to clean the filter with compressed air cleaning, almost all of the dust is removed. Surface loading technology has existed for decades, even for the capture of very fine smoke and fume particles generated by metal cutting application, but this typically required coating the filter with a material like crushed limestone or diatomaceous earth as an initial pre-coat. In some applications, this dust coating would need to be replied as it was cleaned off and in some instances, continuously applied to provide high level of efficiency and to improve filter life.

The Nanofiber advantage

The advantages of surface loading the collected dust are many. Using nanofibers as the way to surface load dust may be the best option for your dust collection need.

- Easier cleaning – cleaning dust off the surface of the filter, as compared to pushing out of the depth of the media, is easier and faster. Less dust on the filter means lower operating pressure drop, increased airflow at capture points, less cleaning cycles and less compressed air usage reduces operating cost and increases system efficiency.

- Smaller dust collectors – sizing of dust collectors is based on dust size, quantity of dust, and airflow. When filters are easier to clean because dust remains on the surface, more airflow per cartridge can be realized. This results in smaller collectors, less filters, and overall, lower cost to purchase and lower cost to operate and maintain.

- Energy reduction – with surface loading, better cleanability of the filters, and no dust trapped in the depth of the media, pressure drop across the filter remains lower. Using a VFD to maintain constant airflow; energy to run the fan is saved, reducing the system operating cost.

- Reduced maintenance – when filters clean easier and pressure drop stays lower, longer; the result is filters that last longer. With less time needed for filter changing, less filters to purchase, and less disposal costs, maintenance and operating costs are a real savings for the facility.

Depending on your facilities need, type of dust, and other application variables, as well as whether you need a new system or just upgrades to an older system, filters utilizing latest nanofiber technology likely will provide operational and maintenance benefits in the form of lower operating costs.

Nanofiber cartridge filters are set to become a new standard

Nederman’s new MCP dust collector, as well as most similar systems on the market, use cartridge filters. The blended paper cartridge media (type 175) has long been a standard component of our dust collection systems, but it is now being replaced by the new type 178 cartridge, blended paper with nanofiber. Equipped with nanofiber filter media, type 178 media can be used in many different systems and devices, such as Nederman stationary filter systems for dust- and fume extraction MCP, FMC, LCP, MJC, MJC Mini and SiloSafe as well as our mobile dust collectors and fume extractors FilterBox and FIlterCart, It can be retrofitted into several types of older machinery and will become a standard component in all Nederman cartridge dust collectors.

In the future, we are likely to see nanofiber filter media continue to evolve, with even smaller fibers than today. This would, for example, make for even better surface loading, simpler cleaning, and increased particle collection efficiency. Stay connected with Nederman to learn firsthand when these future improvements will be available and other technology improvements that may benefit your facility.

If you have any questions about nanofiber filter media, and Nederman’s work in this field, you are welcome to contact me at dan.rousseau@nederman.com. You will also find plenty of other articles here at the Nederman Knowledge Center, covering areas such as combustible dust filtration, robotic welding fume extraction, 3D printing dust and fume extraction

Loading...