- Home

Nederman SAVE- Airflow control

Optimise your filter performance for energy saving extraction with Nederman SAVE

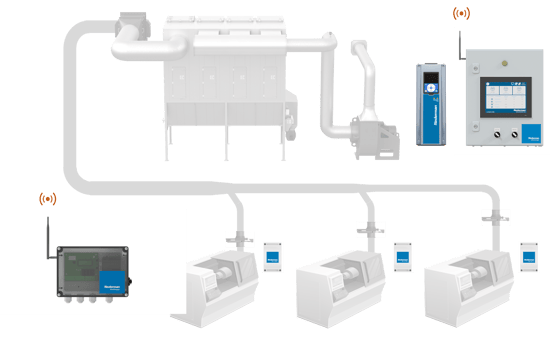

Intelligent airflow control system that saves energy, enhances performance and tracks process utilisation on new or existing industrial filtration systems

Traditional dust collection systems are designed to operate continuously regardless of whether extraction is required. This leads to wasted energy, increased wear and tear, increased maintenance costs and suboptimal filtration performance. Nederman SAVE airflow control system tracks the process operation and adjusts fan operation to deliver the required airflow as it is required using the minimum energy required to maintain desired performance.

How does Nederman SAVE work?

Through monitoring machine and process information, SAVE determines the precise amount of airflow and pressure required at each extraction point for effective dust extraction and safe material transport. The fan operation is then adjusted based on the actual operational demand resulting in energy savings, increased combustible dust safety and reduced system wear and tear. The machine data collected by the system can then be used to track machine utilisation through Nederman Insight. Nederman SAVE can reduce energy consumption by up to 70% when compared to traditional dust collection systems and delivers additional values in the design, operation and maintenance of dust collection systems.

With the optimised airflow and improved dust collector performance, customers experience a wide range of values with Nederman SAVE.

|

|

Energy Reduction |

|

|

Safety and Reliability |

|

|

Productivity Data |

|

|

Increased capacity |

|

|

Reduced maintenance |

|

|

HVAC Saving |

|

|

Reduce noise |

For New or Existing Dust Collection Systems

Retrofit Existing Installations

SAVE is a flexible technology that adapts to most existing dust collection systems including baghouses (reverse air or pulse jet), cartridge collectors, systems with multiple fans and more. In addition to energy saving, retrofits can breathe new life into underperforming systems and or create additional capacity for for machine expansion.

New Dust Collection Systems

Including SAVE in the design of your new dust collection allows the system to be optimized from day one. SAVE may allow for smaller system design reducing capital expense, system footprint and creating room for future expansion. With the energy savings and IoT ready technology, you are future proofing your factory and profits.

Case Story

Let us show you how Nederman SAVE made a huge impact on one of our customers with a payback time on investment under 7 months! If you can`t see the video please go to our Youtube channel Nedeman Youtube

Monitor Operation, Energy Savings and Productivity

Nederman SAVE directly integrates with our cloud-based IIoT platform Nederman Insight that provides real time monitoring, visualization and tracking of system performance, including customized dashboards, alarms and reports. Live data is accessible remotely via the web and mobile devices and stored in the cloud for trending and performance analytics.

- Monitoring

Monitor system status, energy savings and machine operation data within a user-friendly dashboard developed specifically for industrial ventilation applications

- Process Data

View live utilization data for each machine connected to the SAVE system. Access to historical and trending data allows you to analyze and improve operational productivity.

- Energy Tracking

Receive regular energy saving reports directly to your Inbox or export data on-demand to help justify grants or document sustainability activities.

- Alarm Notifications

Alarm logs and service tracking features enables efficient planning and troubleshooting to avoid costly downtime.

Contact a Nederman SAVE expert

Go to the Nederman SAVE product page

Loading...