On-Site Inspections

Delivering the Promise of the Clean Air Company

Because, uptime is money

Nederman filtration systems as an integral part of your production. Properly executed inspections help to avoid possible downtime due to worn parts or equipment failure. Nederman inspections include:

- Comprehensive inspection of dust/fume filtration system

- Inspection and evaluation of fire protection equipment (if applicable)

- Post inspection report with findings and corrective actions

- Genuine replacement parts available based on findings

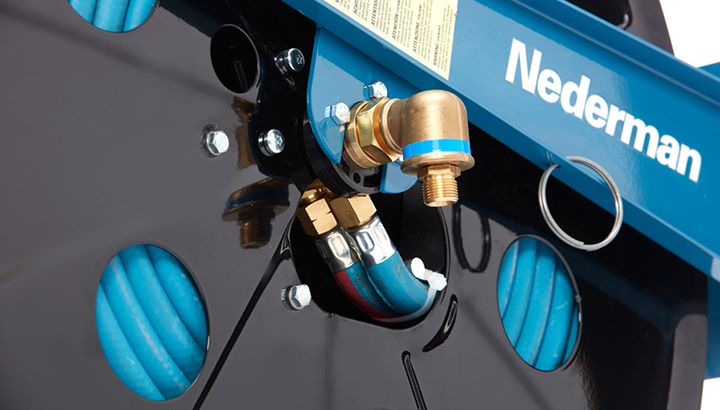

Maintain a Safe Working Environment

Combustible dust is one of the most serious risks caused by dust in manufacturing environments. Nederman dust collection solutions are designed to prevent the danger of dust and gas explosions by creating a safer environment using ATEX approved solutions, such as dust collectors, extraction arms, industrial vacuum cleaners and explosion isolation flap valves. While it is important to design a safe system, it is equally important to have a maintenance and inspection program to maintain effective dust control and ensure spark detection and chemical isolation components are properly functioning. Nederman technicians are trained and certified to perform inspections on all safety equipment provided with our Dust/Fume Filtration Systems.

Tailored Multi-Year Service Agreements

The goal of Nederman’s Aftermarket Team is to provide you with the level of service and support that aligns with your maintenance strategy and capabilities. Because we understand all of our customers have different needs, we pride ourselves in co-developing Service Agreements that ensures the right level of equipment uptime, filtration performance, and safe working environment. Here are some of the elements that can be included in a service agreement with Nederman:

- Multi-Year agreements up to five (5) years

- Comprehensive inspections that can be setup annually, bi-annually, even four(4) times per year

- Scheduled Bag/Cartridge Changeouts based on your company’s maintenance policy

- Access to Insight Dashboard (myAir Subscription)

- Service (Troubleshooting, Bag/Cartridge Changeout, etc.) and Spare Part Discounts

- Provider of genuine replacement parts

- Flexible Billing Options

Request an Inspection!