- Home

- Industries

Woodworking

How to keep your woodworking installation safe, compliant & energy efficient

Dust generated by woodworking manufacturing processes creates serious health and safety risks to workers and assets. We will guide you on how to implement NFPA compliant wood dust collection solutions to secure your workplace.

Dust generated by woodworking manufacturing processes must be properly controlled to reduce health and safety risks. Left uncontrolled, sawdust presents occupational hazards, including:

- Poor indoor air quality, which can negatively impact worker health.

- Dust accumulation on machinery, causing accelerated wear and tear.

- Combustible dust risks, increasing the likelihood of fires and explosions.

Whether in small or large-scale workshops, utilizing hand tools or automated CNC machines, woodworking manufacturers need effective, NFPA compliant dust collection solutions to create a safe and productive work environment. Additionally, proper handling of collected wood waste is essential for sustainability and profitability.

NFPA-Compliant Dust Collection Solutions

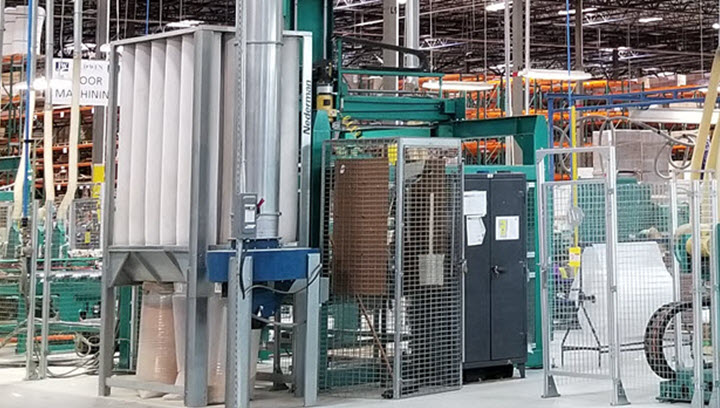

Nederman is The Clean Air Company, offering a complete line of NFPA 660:2025 compliant wood dust collection equipment with the following benefits:

- Improved worker and facility safety

- Energy-efficient operation

- Flexible systems for future expansion

- Healthier, cleaner environment

- Extended machinery lifespan

- Increased productivity

- Enhanced product quality

A Global Leader in Wood Dust Collection Solutions

As the world’s leading provider of industrial air pollution control equipment, Nederman delivers complete NFPA compliant solutions for woodworking dust collection. Our expertise extends to small and large applications, from manual workspaces to fully automated CNC operations.

- Industry Expertise - Over 80 years of experience and thousands of successful installations.

- Comprehensive Approach - Manufacturing a full range of dust collectors, filters, and accessories, plus installation, commissioning, and service support.

- Wide Solution Range - Robust systems designed for woodworking industry needs.

- Quality and Reliability - Engineered to minimize downtime and optimize efficiency.

- Global Presence - Regional sales offices and distributor networks ensure local support.

- Sustainability Commitment - Energy-efficient, eco-friendly solutions designed to reclaim waste material.

Nederman is ISO 9001:2015 and ISO 14001:2015 certified at each of our global manufacturing locations assuring our commitment to quality and sustainability across all global manufacturing locations.

Workplace Hazards and NFPA Compliance

Airborne Dust Exposure

Wood dust exposure is a serious health hazard. The International Agency for Research on Cancer (IARC) classifies wood dust as a Group 1 human carcinogen, while OSHA sets strict exposure limits. The preferred control method is a properly designed dust collection system, which captures dust at the source.

Combustible Dust

The risk of fires and explosions from wood dust is well-documented. The Combustible Dust Safety Institute estimates that 25% of all industrial combustible dust incidents occur in woodworking facilities.

The National Fire Protection Association (NFPA) sets standards for dust collection system design and safety. Previously, NFPA 654 and NFPA 664 provided guidance for combustible and wood dust applications, respectively. However, these standards are now consolidated into NFPA 660-2025, which offers a comprehensive framework for safe dust collection system design and operation.

Additionally, ATEX directives provide valuable guidance on equipment design and workplace protection to ensure safe and compliant solutions.

Because combustible dust regulations can be complex, working with experienced industry professionals is essential to ensure full compliance and risk mitigation.

Wood Waste Management

Wood waste can be profitably recycled into new materials (e.g., MDF boards) or converted into biofuel energy. Well-designed and efficient wood waste handling systems are now an integral part of the woodworking industry. As a global leader in industrial air filtration, Nederman offers solutions tailored for centralized production plants and small-scale woodworking operations.

The Clean Air Company

Nederman provides a comprehensive, NFPA compliant approach to clean air solutions for the woodworking industry. We see ourselves as partners in your operation, committed to delivering safe, productive, and sustainable dust collection solutions. Our turn-key systems include:

- System design tailored to your facility's needs

- Installation, commissioning, and ongoing service to ensure optimal performance.

- Advanced technology integration, including smart monitoring and filtration.

Shaping the future of Clean Air

Nederman’s 2,400+ employees work daily to develop innovative clean air solutions. Our myAir approach, featuring:

- SmartFilter technology, for efficient and sustainable dust filtration.

- Insight IoT platform, providing real-time monitoring and predictive maintenance

- Comprehensive service support, to keep your system operating efficiently.

For woodworking manufacturers, this means enhanced performance, safety, and cost savings. With Nederman as your partner, you can focus on your business while we handle your dust collection needs.

Contact Us

Discover how NFPA compliant wood dust collection solutions can secure your workplace and enhance productivity. Contact Nederman today to learn more!

Contact a Clean Air Expert!

Safety and compliance - Ensure a safe and compliant workplace in woodworking industries

Exposure to airborne wood and sawdust is a worker hazard to take seriously. The International Agency for Research on Cancer (IARC) considers wood dust a Group 1 human carcinogen and global health and safety organizations including the HSE and OSHA have set stringent exposure limits and recommends an exhaust ventilation system capturing the dust at the source as the preferred protection approach.

Combustible Dust is one of the most serious risks caused by dust in manufacturing environment

The Combustible Dust Safety Institute estimates that roughly 28% of all industrial combustible dust incidents occur within woodworking factories. Combustible dust standards may seem confusing and difficult to understand as it involves the full design, operation and maintenance of the complete dust collection system.

Ensure compliance with combustible dust regulations

All Nederman solutions are fully compliant with ATEX and NFPA. These standards include requirements on duct system design, filter construction, controls, explosion isolation and proper maintenance of the dust collection system. Nederman has developed a rigorous combustible dust sales process that keeps our team informed of the latest standards and helps advise our customers on achieving compliance.

Learn more about combustible dust

Energy efficiency - Save energy in the woodworking industry

Wood manufacturing is a heavy energy consuming industry. Ensuring that your air filtration system is designed using best practices and best available technology to optimize process efficiency and energy use is critical to reducing operational costs and increasing profits. Reclaiming wood waste for sale or energy production is another important aspect of sustainability in wood manufacturing.

How to reduce energy consumption in wood manufacturing

Modern technology provides opportunities for more energy efficient operation than ever before. Variable Frequency Drives (VFDs), reverse air technology, advanced filter media and intelligent controls all can yield substantial reductions in energy consumption as well as optimize the process efficiency. Integrated IIoT connections provides effective real-time communication which enables to take control of the energy consumption in a whole new level. Regular service and maintenance on the filters, fans and material handling devices also play a critical role in energy efficient operation.

Wood waste management for a sustainable and circular industry

Instead of sending wood waste to landfills, it can be repurposed and sold as wood chips, mulch, or used as biomass for energy production. By implementing wood waste recovery programs, wood manufacturers can not only reduce their waste and disposal costs but also contribute to a circular economy and improve their sustainability. We are very experienced in integrated material handling systems into our filtration solutions in a safe and effective way. Further, proper handling of the collected wood waste is also an important aspect of dust collection system that may impact both profits and sustainability.

Did you know?

According to Dust Safety Science, the woodworking industry accounts for approximately 28% of all global, combustible dust incidentsWhat is combustible dust?

- Combustible dust, also known as explosive dust, is a by-product created from manufacturing processes that involve combustible raw materials

- It can be any fine material that can catch fire and explode when mixed with air and many materials can become combustible dust under specific conditions

- The small dust particles are a deadly hazard in many workplaces as they risk causing explosions that can potentially kill or injure workers and destroy machinery or even entire facilities

Loading...